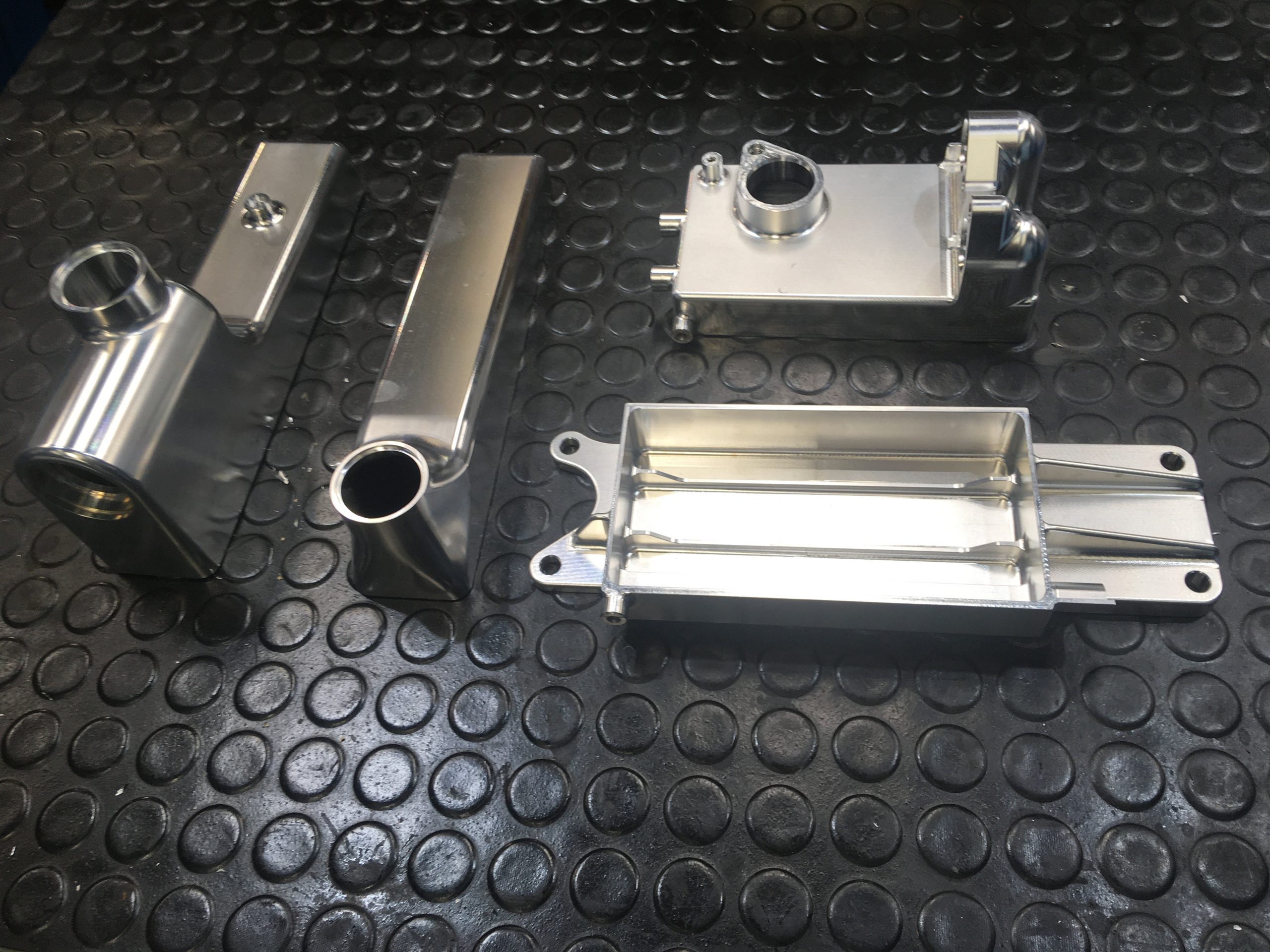

A selection of parts machined using a range of different strategies. Lots of compound curve surfaces and draft angle faces of which 5 axis work really excels at processing. Very tight immovable deadline, tight tolerance designs. All delivered satisfactorily by us.

CNC

CNC Machining – Simultaneous 5 Axis

A nice example displaying various machining strategies.

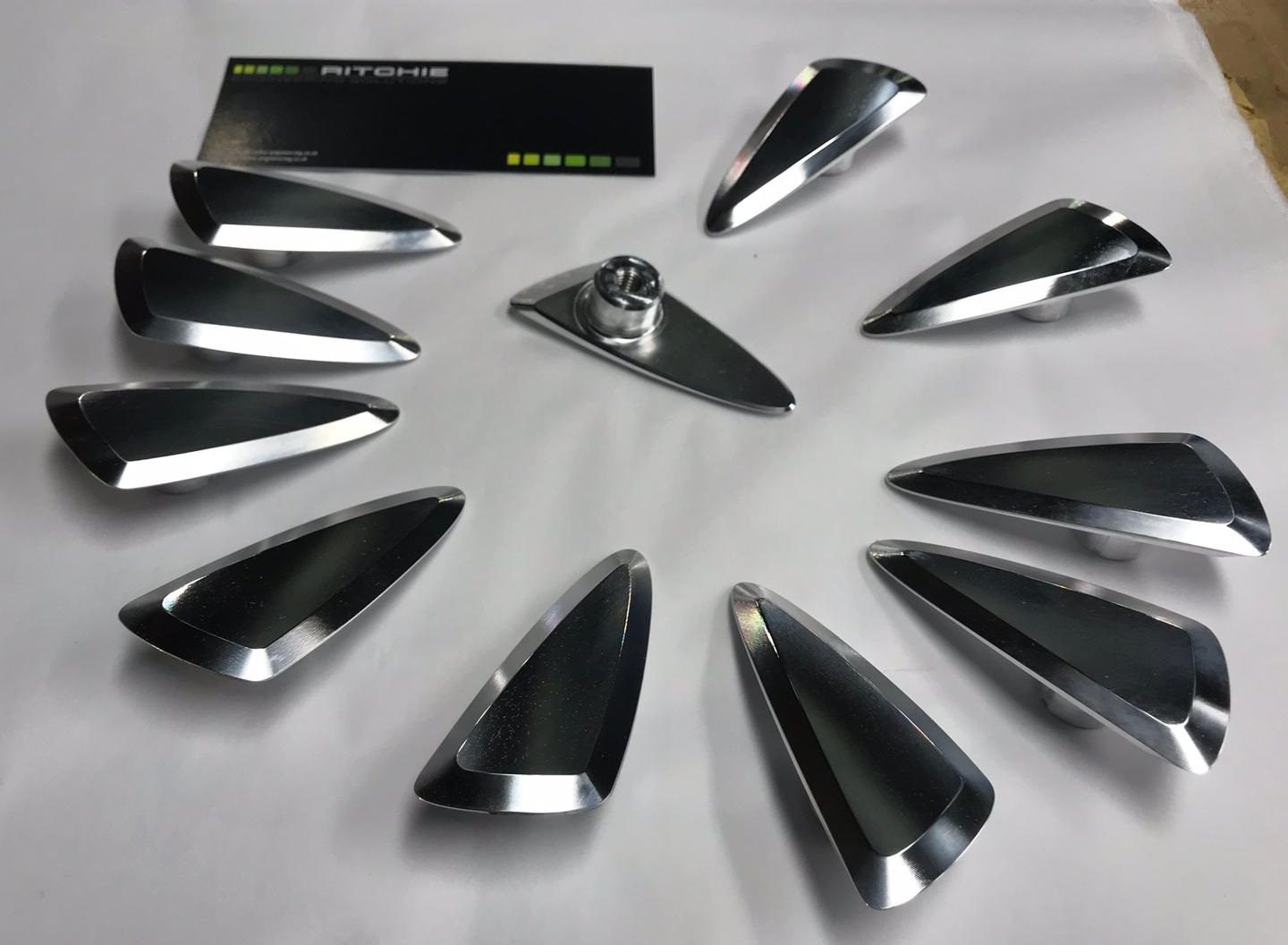

CNC Machining, Mill-Turn

Mill-Turn. Or is it Turn-Mill? Whatever! Our Mazak made a good job of these. We used a custom carbide cutter to apply the chamfer (on the rearside too) at the same time as the peripheral cuts. Faster process time = cheaper part for the customer.

CNC Machining – Simultaneous 5 Axis

An interesting part that required a mixture of 5 axis positional and 5 axis simultaneous strategies. The required cosmetic finish varied, hence the mixture of coarse and smooth finishes. A batch of these were produced on our Matsuura MAM 72 35V, which ran for 12 days non-stop (24-7). The last one to come off was … Read More

CNC Parts

Fascia Panels These fascia panels for a Professional Audio OEM required us to design some custom work holding to ensure the milling operations proved reliable and the component quality consistently high. Quality is particularly important for these items; the client is recognised to be one of the market leaders in the professional audio high-end sector … Read More

CNC Machining – Simultaneous 5 Axis

A simple part, but with a high quality surface finish requirement as Class A surface for an automotive OEM client. Our Matsuura running at 20,000 rpm made a nice job of this.

CNC Machining – Alternator Bracket

Billet machined alternator bracket for a Motorsport Rally client. Ritchie Engineering designed, analysed (stress & vibration) and manufactured.

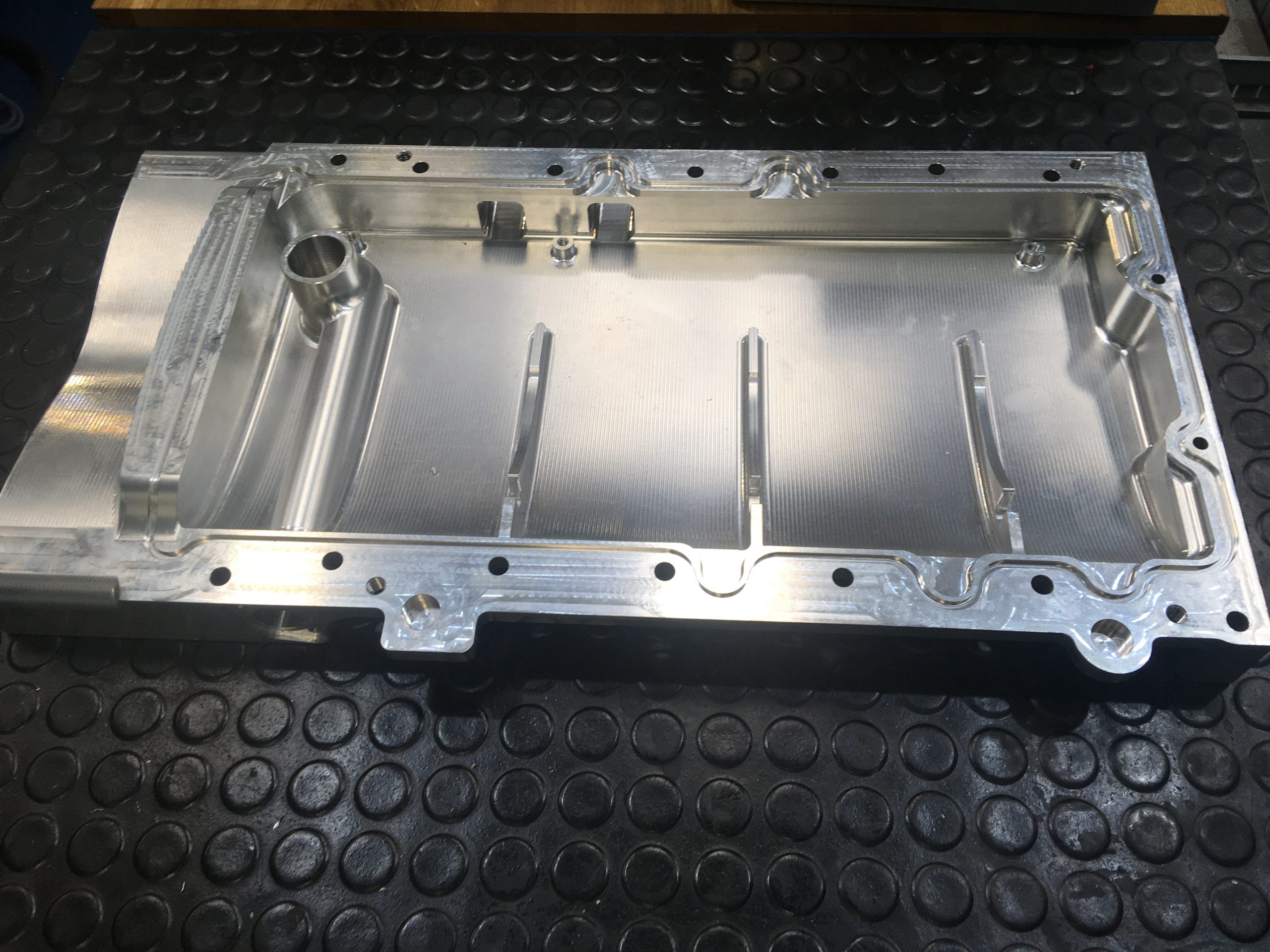

CNC Machining

A nice example of machining recently undertook for an automotive client, comprising a mixture of classic 2.5 D machining, surface scanning and pocketing.

CNC parts

Automotive Components An example of some machined parts for an automotive OEM client. Not overly complex, but a mixture of tight tolerance control and surface finish demands required careful attention to detail and work holding. We were happy with the way these came out, and more importantly – so was the client.

Best of British Engineering with Norton Motorcycles

When the British motorcycle manufacturer decided to champion Great British engineering with its new V4 race born road bike Ritchie Engineering were just the specialists they needed to help supply a number of complex machined components. Working with Norton from the earliest concept designs up until market release, we helped them overcome a range of … Read More